Industrial Air Quality

Solutions

Air quality has a significant impact in the industrial sector as it’s directly related to employee and process safety. The benefit is improved operational performance and environmental improvement by reducing potential outdoor contamination.

Bringing clean air to industry

Breathing clean and pure air should not be limited to opened environments. Healthy and safe air conditions must be ensured within the workspace in manufacturing plants and facilities. At the same time, it’s a social responsibility for the industrial sector to reduce outdoor the amount of contamination generated. Air filtration is critical to ensure this.

Improved air quality for an enhanced and safer operation

Our dust collection solutions provide a cleaner indoor air for increased safety and to provide healthy conditions for workers and operators by reducing their continuous exposure to the dust and airborne particles. Also, dust collection supports the process by mitigating fire risk or explosion when handling combustible dust, making the process NFPA compliant.

In certain processes, the dust generated is not waste, but part of the product that was expelled into the indoor atmosphere. To solve this issue, our portfolio comprises several filtration units aimed at ventilating dust with the possibility of returning the collect product back into the process. A significant cost saving in addition to an improvement in the indoor air quality.

AAF dust collectors have been designed to ensure a lower pressure drop and minimum compressed air usage. The enhanced performance of our pulse cleaning system combined with the high efficiency of our filtration media results in a longer life cycle both for the equipment and the filters, ensuring cost savings and a reduced total cost of ownership.

With a continuous focus on the customer needs and the goal of providing a satisfactory experience while ensuring superior performance, our equipment is compact sized to reduce floor print, plug & play for a quick start-up and highly versatile with different configurations, options and final layouts. They provide an easy and agile maintenance, with quicker and fewer change-outs of the bags and cartridges.

AAF INDUSTRIAL AIR QUALITY SOLUTIONS

BGRS, Inc. founded in 1976, is a pioneer in solids handling, and portable combined abrasive blasting, dust collection and recycling systems for the paint industry. We have been active in the solids material handling and dust control equipment manufacturing since 1980. Our design and manufacturing facility in northwest Harris County has been serving the chemical, petrochemical, abrasive blasting, coating, manufacturing, food service, water and wastewater, energy conveyance, and pharmaceutical industries.

We have teamed with multiple industry partners in the development of prototype design systems for combined blast and recovery systems, mixing tanks, abrasive stripping systems, oilfield de-dusting and collection systems, and specialized air handling, dehumidifying, and temperature regulation systems. BGRS designed and manufactured an oversized blast room with dust control, abrasive and stripped material recovery, recycling, and classification for the US Air Force to remove coatings from combat fighters in preparation for application of new coatings.

In the early 1990s, BGRS also designed a computer controlled soft media dry stripping system for the integrated circuit (IC) industry to precisely remove excess conductive material from computer boards. This system allowed for the stacking of boards in 3-dimensions without the use of riser converters. The system was eventually patented by our client.

We also provide multiple clients with design and construction of double dump gate/airlock valves, mixing hoppers, silo bin vent systems, abrasive material classification systems, lime slurry mixing and delivery systems, and custom fabrication of fluid control devices and structural steel elements.

Our goal is to increase the safety of your facilities by supporting the prototype development of and providing dust collectors and de-dusting systems from 2,500 cfm systems to over 60,000 cfm systems. We have a proven reverse-pulse filter cleaning design with our built-to-order polyester felt cartridges with client-reported usable life frequently as long as 10 years.

Please view our other areas for details associated with each of our equipment and service offerings.

A comprehensive portfolio to meet your needs

The widest range of dust collectors designed to meet the challenges of the most demanding industrial applications while reducing your total cost of ownership.

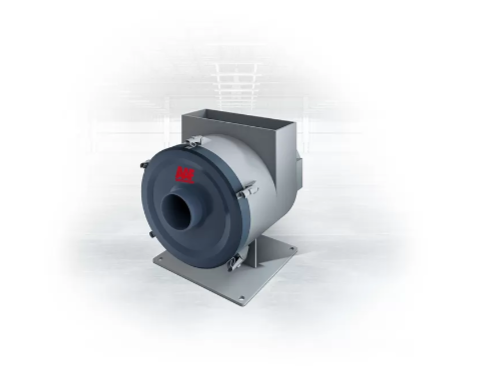

DRY COLLECTORS

Highly efficient cartridge and bag solutions with simple maintenance, longer life cycle, and reduced compressed air usage.

WET COLLECTORS

A wide range of configurations, sizes, and filtration options to efficiently use the power of water for industrial dust removal.

OIL MIST COLLECTORS

Efficient for the removal of hazardous mist from machining processes ensuring space savings and a simplified maintenance.

REPLACEMENT PARTS

Energy savings and excellent dust release ensured with our nanofibre leading technology and other superior performance medias.

Call BGRS,Inc today at (281) 890-6862 or Contact Us to learn more about our equipment and services.